From Values to Velocity: How Kinetic Technologies is Revolutionizing Manufacturing Automation

In an era where manufacturing faces unprecedented challenges—from labor shortages to increasing demand for customization—companies like Kinetic Technologies LLC are stepping up to bridge the gap between human expertise and automated efficiency. Mark Barglof, President and Owner of Kinetic Technologies, shares insights about his company's unique approach to robotic solutions and how they're helping manufacturers overcome their growth challenges.

The Journey to Kinetic Technologies

Mark's path to founding Kinetic Technologies wasn't conventional. With a background in product development across companies of various sizes, he previously led a successful startup focused on driverless technology using machine learning, artificial intelligence, and computer vision. After selling that company, he noticed a critical gap in the manufacturing world."I came out of product development where we were doing agile software development with very rapid iterations," Mark explains. "I noticed that our mechanical engineering teams were struggling with this agile approach—how do we rapidly engage with engineering teams and build mechanical components?"

This observation, combined with his experience in high-volume manufacturing, led him to explore automation through robotics integration. What started as engineering prototyping soon evolved into addressing complex challenges in robotics, automation, and manufacturing.Values as the Foundation

What sets Kinetic Technologies apart isn't just their technical expertise—it's their unwavering commitment to core values. Mark's approach is refreshingly different from the typical "fake it 'till you make it" startup mentality.

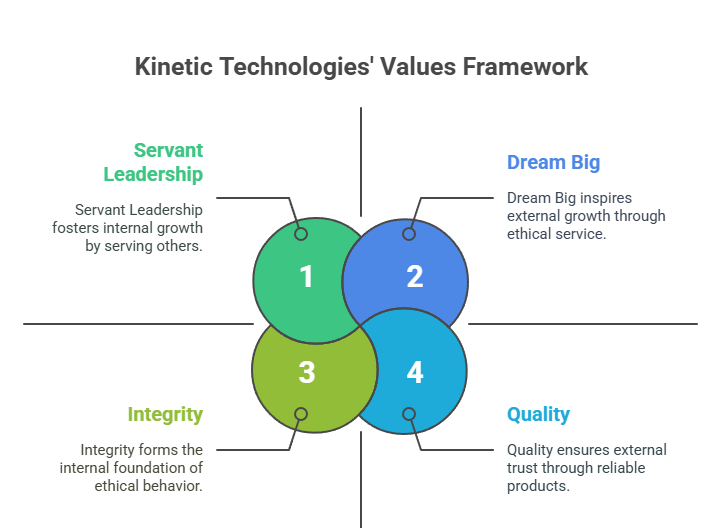

"It isn't necessarily what you do, it's how you do it," Mark emphasizes. The company's values structure is built like a pyramid:

- Integrity forms the foundation: "Do not lie, cheat, or steal, nor tolerate anyone who does."

- Quality builds upon integrity: "Quality is a physical manifestation of our integrity values. We can't say we have high levels of integrity and deliver substandard products."

- Servant Leadership follows naturally: "When we do things ethically and provide quality products, we look at whether we're doing this selflessly—to serve our customers, employees, community, and suppliers."

- Dream Big comes last: "Only when we do it ethically, have a quality product, and serve others can we dream big and achieve great things."

This values-driven approach extends to their business model. Mark's goal is radical transparency: "I want our customers to know that if they looked at the books and saw the value generated from our products versus our profit, they'd say 'this is extremely unfair—we make so much more money than you ever made in profit.”

Specializing in Welding Automation

Kinetic Technologies has found its niche in welding automation—a space that Mark describes as still being "an art form" without mainstream automated solutions. Unlike other manufacturing processes that have been largely automated over the past 50-60 years, welding remains heavily dependent on skilled human operators.

"We see time and time again companies saying, 'We're not trying to get rid of anybody. We just want to keep up,'" Mark notes. "They have amazing welders, but they want to scale their company and it's really hard to find people to fill those particular roles."

The company serves diverse industries across the United States and Canada, from AI data center manufacturing components to domestic semiconductor manufacturing, transportation, and beyond. Despite the variety, the needs are consistent: increased productivity, scalability, and ultimately, profitability.

A Unique Approach to Project Delivery

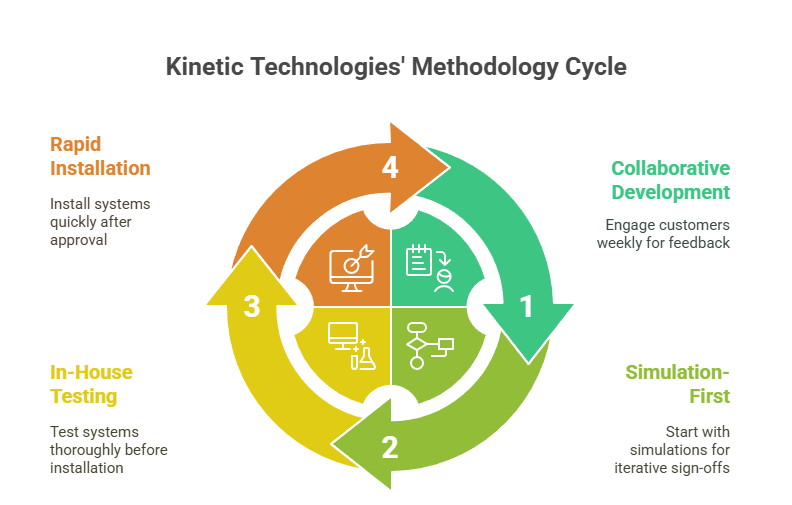

Kinetic Technologies has developed a distinctive methodology that sets them apart from competitors. Their approach includes:- Collaborative Development: Weekly touchpoints with customers throughout the project, using agile Kanban methodology with emerging requirements.

- Simulation-First: Projects begin with simulations showing the end goal, with iterative sign-offs along the way.

- In-House Testing: Perhaps most importantly, they set up and run complete systems in their own facility before installation. "Everything is designed knowing we need to set it up here, tear it down, go to another location, and bring it back up again."

- Rapid Installation: Once tested and approved, installation typically takes 3-5 days, with the team working weekends and overnight if needed.

"The thing I really abhor is 'fake it 'til you make it,'" Mark states firmly. "You're going to get stuck in a robotics project that really stinks if the first time the whole system comes together is in your facility with your parts."

Growth Through Relationships

When it comes to business development, Kinetic Technologies has found that authentic relationships trump traditional sales tactics. "Outbound sales is the least effective," Mark admits. "Usually somebody is not going to go, 'Oh hey, thanks for that cold call. Now I'm ready to kick off a potentially multi-million dollar automation project.'"

Instead, the company grows primarily through word of mouth and repeat customers. Their approach is to become an extension of their clients' teams, building trust through consistent delivery and quality execution.

"We help to select people that are going to promote our values," Mark explains. "We evaluate our customers just as they evaluate us."

Real-World Impact: A Success Story

Mark shared a recent project that exemplifies their values in action. A Western New York company involved in data center coolant systems approached them initially for welding fixtures.

Through collaborative discussions, Kinetic discovered the client was aggressively attacking a new market but needed professional guidance.

Despite other providers saying automation was "impossible" for their specific parts, Kinetic took on the challenge. The project involved:

- Flying out to assess the situation firsthand

- Providing training resources typically used for their own employees

- Transparent communication when initial attempts didn't work perfectly

- Delaying installation by a week to ensure quality (which the team felt terrible about, but the client appreciated)

- Successful installation in just five days

The Future of Kinetic Technologies

As Kinetic Technologies continues to grow, they're doubling down on welding technology while exploring new applications. They're partnering with AI-based welding solution providers and looking to replicate their welding success in other robotic applications like pick-and-place, machine tending, and palletizing.

"Welding is probably one of the more complicated applications, but it's been fantastic because it gives us the experience and breadth for other use cases," Mark notes.

Key Takeaways for Manufacturing Leaders

The conversation with Mark Barglof reveals a deeper truth about modern manufacturing: success isn't just about technology—it's about values, relationships, and a genuine commitment to customer success. In an industry often focused on quick fixes and flashy solutions, Kinetic Technologies proves that integrity, quality, and servant leadership can be powerful differentiators.

As manufacturers continue to face challenges around labor shortages, just-in-time production demands, and the need for consistent quality, companies like Kinetic Technologies offer a path forward that doesn't sacrifice human values for technological advancement.

For manufacturing leaders considering automation, Mark's advice is clear: look for partners who will walk alongside you, who test their solutions before implementation, and who view success not in terms of their own profit, but in terms of the disproportionate value they can create for their clients.

In the end, it's not just about the robots—it's about the relationships and values that guide how those robots are implemented.

___________________________________________________________________________________ This is brought to you by MacRAE’S — trusted by North American businesses for over 100 years. As a leader in B2B digital marketing, we help industrial and manufacturing companies struggling with stagnant growth, or leads. By leveraging advanced AI integration and automation in our SEO and lead generation programs, we help you appear prominently on Search and in AI-powered results — including ChatGPT, Gemini, AI Overviews, and Local Search. This drives significantly more qualified traffic to their websites, resulting in stronger lead flow and increased revenue — crucial in today’s highly competitive digital landscape. Learn more at macraes.com today.